Description

Giới thiệu sản phẩm

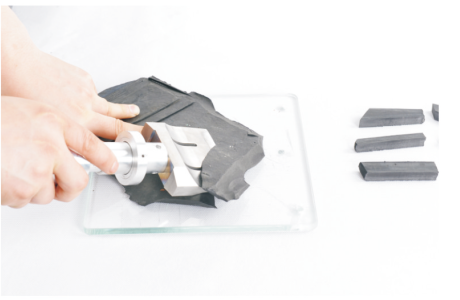

Máy cắt siêu âm là một loại thiết bị sử dụng năng lượng siêu âm để cắt thay vì sử dụng lưỡi cắt truyền thống, cắt siêu âm có ưu điểm là cắt mịn, đáng tin cậy, cắt xén chính xác, không biến dạng, không nâng cao, mờ, kéo sợi, nhăn, v.v. Nó có thể tránh lưỡi cắt thô, cạnh coke, bóng mờ và các khuyết điểm khác của máy cắt laser. Máy cắt siêu âm được sử dụng để cắt cao su, vải tổng hợp, vải, nhựa, kim loại tấm, thực phẩm, v.v.

Thông số kỹ thuật:

Mã sản phẩm.: HSC40

Tần số: 40KHz

Máy phát điện: ZJS-100L

Công suất tối đa: 40W

Trọng lượng 2.5Kg

Kích thước:155W×265L×170H

Handle:Φ32×170

Phụ kiện:Chân chuyển đổi1pc, lưỡi cắt 25pcs , 1.5mm Cờ lê lục giác 1pc

Đặt vít M3×4L 2pcs

Lợi thế

Cắt nhanh, chính xác, cạnh cắt mịn của vật liệu!

Sử dụng đơn giản!

Dễ dàng cài đặt!

Dễ dàng hoạt động!

Máy cắt cao su

Máy cắt siêu âm cao su là thông qua năng lượng siêu âm, sẽ được cắt vật liệu nóng chảy cục bộ, để đạt được mục đích cắt vật liệu. Dưới đây là các bộ phận và chức năng của nó:

Máy phát điện: Nó có thể chuyển điện dân dụng 50-60Hz sang nguồn điện tần số cao (15kHz-100kHz) của công suất lớn, sau đó cung cấp cho đầu dò.

Bộ chuyển đổi: Có thể chuyển năng lượng điện tần số cao sang năng lượng rung động của máy.

Booster: Được sử dụng để kết nối và cố định đầu dò và còi. Khi mở rộng vòng xoay của đầu dò, nó sẽ chuyển sang còi.

Lưỡi dao: Sử dụng để gửi năng lượng và áp lực của máy đến vật liệu làm việc

Thông số kỹ thuật

Ưu điểm của máy cắt siêu âm:

1. Có thể áp dụng thiết kế làm mát bằng không khí và làm mát bằng nước để thích ứng với các điều kiện và môi trường làm việc khác nhau

2.Tốc độ cắt được cải thiện đáng kể, và hiệu quả tăng hơn 10 lần so với dao cắt truyền thống.

3. Sử dụng đầu dò siêu âm công suất cao làm bộ phận rung để đảm bảo công việc ổn định lâu dài

4. Có thể tùy chỉnh đầy đủ các loại dao cắt, và các loại dao cắt liên quan theo quy trình của khách hàng

5. Nó có thể cắt tất cả các loại sản phẩm khó cắt bằng các công cụ thông thường, giải quyết các vấn đề về sản xuất và gia công

6. Có thể lắp các lưỡi có độ cứng cao, và có thể thay thế các lưỡi cắt, giảm chi phí sử dụng

7, dễ dàng cài đặt và sử dụng, hầu như không thay đổi quá trình cắt ban đầu

8, độ chính xác cắt cao, bề mặt cắt tốt

Ứng dụng chính

Nẹp lốp; nylon; lớp nhựa đai thép; dây ni lông; lớp lót bên trong; vách ngăn; khối chóp; vòng tam giác và như vậy;

Ứng dụng lĩnh vực khác:

Bo mạch in; sợi tự nhiên; Sợi tổng hợp; vải không dệt; nhựa tổng hợp mỏng; làm mô hình; tất cả các hình thức của giấy; phim ủng hộ; thực phẩm (bánh, đường, thịt).

Description:

Hệ thống cắt thực phẩm siêu âm thường được sử dụng để cắt các loại thực phẩm sau:

1. Phô mai cứng và mềm, bao gồm các sản phẩm có chứa các loại hạt và trái cây

2.Sandwiches, wraps và pizza cho các ngành công nghiệp ăn uống

3.Nougat, thanh kẹo, thanh granola và thanh ăn nhẹ lành mạnh

4. thịt và cá đông lạnh

5. bánh mì hoặc các sản phẩm bánh

Máy cắt thực phẩm siêu âm

Thông số sản phẩm

| Xuất xứ | China | Thương hiệu | Altrasonic |

| Mã sp | HSFC305 | Certification | CE |

| Tần số | 20Khz | Công suất | 800W |

| Đồ dài lưỡi cắt | 305mm | Chiều dài cáp | 3M |

| Bộ điều khiển nguồn | Bước hoặc liên tục | Đầu vào | AC110-240V, 50/60Hz |

Các yếu tố cần xem xét trong quá trình cắt thực phẩm:

● Thời gian rung ban đầu

● Biên độ dao động

● Vận tốc cắt

● Thời gian rung cuối cùng

| Model | Parameters | |

| 1 | HSQ25B-CB | Tần số: 40khz Công suất tối đa: 800W Máy phát điện: Kỹ thuật số Chất liệu: Titannium |

| 2 | HSFC305/HSFC255 | Digital Generator Frequency: 20khz Power: 1000w Length of the knife: 255mm/305mm Material of the knife: Titanium alloy Ultrasonic transducer with booster, fixing frange |

| 3 | HSFC125/HSFC82 | Digital Generator Frequency: 20khz Power: 1000w Chiều dài lưỡi cắt: 125mm/82mm Chất liệu lưỡi cắt: Titanium alloy Ultrasonic transducer with booster, fixing frange |

| 4 | HSPC30 | Frequency: 30khz Max Power: 300W Generator: Digital Material thickness: 1mm-5mm |

| 5 | HSQ40B-AB | Frequency: 40khz Max Power: 100W Generator: Analog Material thickness: 1mm-5mm |

| 6 | HSSC40 | Frequency: 40Khz Power: 800W Input: AC100V/AC220V, 50/60Hz Power Controller stepping or continuous Material of blade: aluminum alloy, stainless steel, titanium alloy, alloy steel. Weight: 16kg(including the generator) Accessories: foot switch, additional blade Cooling: compessed air mouth can be installed. |

| 7 | HSF57B-CB | Frequency: 35KHZ Power: 800W Rotary Welding horns Width: 12mm Power Adjust Method: File or Continuous The Horns Surface Hardness: More than HRC56 Real-time Display: Working Frequency and Working Current Synchronizing Wheel Specifications: 46XL Trapezoidal Tooth, Width 16mm Synchronizing Belt Matched: The Length is not more than 730mm, the Width 12mm Allowable Rotation Speed: 100 r/min. Install Bolt: M8, 4 pcs |

Reviews

There are no reviews yet.